Circular construction

We drive circular construction with solutions to reduce, recycle and reuse materials.

We convert plastics and minerals into new materials or energy sources and recycle over 8 million tons of construction demolition materials using our circular technology platform, ECOCycle®.

Reduce

We are building better with less.

To reduce the footprint of buildings and build better with less, we are continuously advancing our portfolio of innovative and sustainable building solutions.

We are reducing the carbon footprint of construction at scale with the world’s broadest range of low-carbon concrete, ECOPact and low-carbon cement, ECOPlanet. Both ranges offer 100% performance with a CO2 reduction of at least 30% compared to standard alternatives.

Our carbon prestressed concrete (CPC) slabs use up to 80% less materials with up to 75% lower CO2 emissions.

DISCOVER OUR BUILDING SOLUTIONS

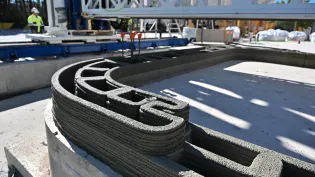

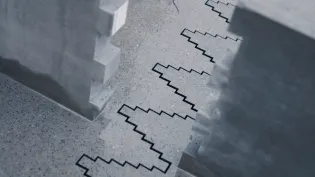

3D printing can use up to 50% less materials thanks to our proprietary TectorPrint 3D printing ink technology.

DYNAMax ultimate high performance concrete optimizes material use in every new building to unlock more usable space. The thin, light precast plates made of high-strength concrete, reinforced with prestressed carbon fibers, have the same load-bearing capacity as standard concrete slabs and are circular by design.

Our range of insulation solutions help make buildings more energy efficient. Elevate’s ISOGARD insulation boards range enables 40% higher thermal performance than standard solutions in the market, avoiding heat loss. Enverge bio-based insulation foam makes buildings more energy-efficient in a nature-friendly way. Meanwhile, Airium insulating mineral foam can be applied in green retrofitting applications to expand a building’s lifespan.

To make buildings last longer, our specialty building solutions include PRB and Cantillana façade systems, Tector advanced mortars and Izolbet tile adhesives.

Recycle

We are a world leader in recycling.

We recycle over 30 million tons of materials across our business every year.

We recycle construction demolition materials (CDM) into new building solutions and convert plastics and minerals into new alternative materials. We also take materials at the end of their life, such as biomass and municipal waste, and turn them into alternative energy sources.

In 2023, we recycled 8.4 million tons of CDM, and we’re targeting 10 million tons by 2024.

ECOCycle® is our proprietary circular technology platform to recycle CDM into new building solutions. With ECOCycle® we can recycle from 10% to 100% of CDM across a broad range of applications. We use decarbonized raw materials in low-carbon cement formulation and recycled aggregates in concrete and fillers for road construction.

Within our ECOPlanet range of low-carbon cement, we offer Susteno, the world’s first cement with 20% recycled CDM inside. Available in Switzerland, Susteno is made using high-quality material taken from demolition projects, resulting in a cement that closes the loop on CDM to build new from the old and preserve nature.

Regenerate

Our building solutions help empower circular cities.

Cities can play a vital role in helping us shift from a linear take-make-waste economy to a circular reduce-regenerate-recycle one. We enable the construction of tomorrow's greener, more sustainable and circular cities, while helping to counter the urban heat island effect. We're also advocating for a regenerative revolution in the built environment.

Duro-Last’s Bright White Membrane reflects up to 88% of the sun’s energy. This ENERGY STAR-qualified membrane also releases energy and heat efficiently, greatly reducing energy costs.

Malarkey 3M™ Cool Roofing Granules include a technology based on granules that reflect 20-25% of the sun’s energy, reducing cooling-related energy needs.

Elevate’s green roofing systems host complex ecosystems with trees, plants and irrigation to enhance urban biodiversity.

Hydromedia permeable concrete is a water management system that rapidly absorbs rainwater – reducing the risk of flooding. It enables urban forests and gardens to grow. By bringing more nature into cities, we can reduce the urban heat island effect and improve air quality.

Our bioactive concrete can be used to build bioactive infrastructure for marine and coastal ecosystems, including artificial reefs.