Building better with less using carbon prestressed concrete

What if you could construct one of the world’s first carbon prestressed concrete (CPC) buildings and achieve significant CO2 and material savings, then dismantle its components for reuse elsewhere? Then going even further – what if you could loan these components out?

“These are the questions we asked ourselves – and this is the answer. It’s a landmark in low-carbon, circular construction,” explains Christophe Berset, Head of New Solutions at Holcim Switzerland. Standing on St Gallerstrasse in Winterthur, Switzerland, he gazes with pride at the newly built Grüze Innovation Laboratory, a 120m2 pavilion that functions as an information center, event location and workshop for sustainable construction.

Pioneering a ‘sharing’ model

to reuse concrete

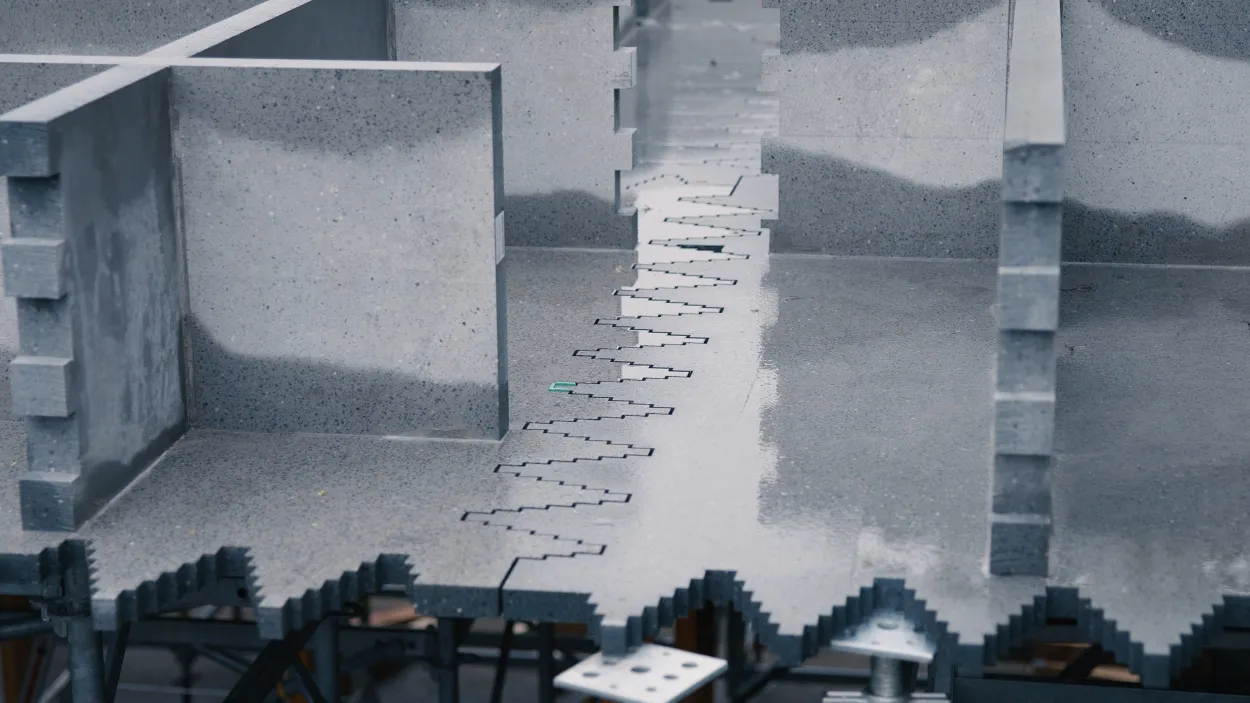

Having opened its doors this spring, the lab is not only one of the world’s first CPC buildings – made using delicate yet resilient reusable panels designed by Holcim – it is also the first CPC structure to be built using a new construction method developed by CPC AG and Zurich University of Applied Sciences.

In comparison with conventional construction methods this yields significant CO2 and material savings, while the CPC load-bearing structures have a significantly better environmental impact. In addition, the project is pioneering a ‘sharing’ model where Holcim loans out the CPC panels for an annual fee.

This opens up a world of new possibilities for customers. Firstly, it reduces the cost of a new development – since they don’t have to buy materials outright or dismantle the building. Secondly, it gives them the option of assembling the structure elsewhere. Finally, the client can ask Holcim to disassemble the structure when it is no longer needed, so we can prepare the components for reuse.

The pavilion is temporary for the next five to 10 years. It is also modular. We can expand the pavilion further in the coming years - modify it, finally dismantle and deconstruct it. The idea is to reuse the material in another project. That’s why we rented it from Holcim. Consciously, so we can reuse the materials again.

Significant material and carbon savings

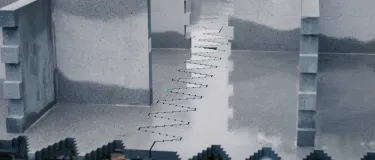

The patented CPC technology – which uses concrete reinforced with thin prestressed carbon strands to create thin, precast concrete plates – offers material savings of up to 75% versus conventional construction methods, and reduces CO2 emissions by two to three times. Moreover, it enables a lightweight concrete construction model that opens up new possibilities for building services and design.

Berset and his Holcim colleagues applied it to bring the building to life, using CPC panels to create the building’s ceilings. Following their manufacture in Holcim’s factory in Essen, Germany, the panels were shipped to the site and rapidly assembled, with the structure created using a ‘plug-in’ system.

When the time comes, the building can be dismantled by Holcim for use in the potential new project Joos mentions. In other projects, the CPC panels will be returned to the factory and prepared for their next ‘life’.

For Joos, the innovation lab is more than just a means of testing and examining new materials in construction: “For the city, it’s a wonderful platform to create new encounters, where one can discuss and find new solutions to major issues of our time, such as sponge cities, circular economy, mobility,” he says.

Use of pioneering CPC technology building is just one way Holcim is Building Better with Less, as we scale low-carbon construction with innovative, sustainable brands from ECOPact to ECOCycle®, empower smart design and advance digitalization, to build progress for people and the planet.

How does CPC technology work?

Made using a proprietary process, CPC panels are reinforced with thin, prestressed carbon strands. Due to carbon’s high tensile strength, and the fact it does not corrode, we can produce load-bearing, slim and durable concrete elements with a much longer service life. CPC panels are manufactured, processed and cut to size in a Holcim plant and can then be quickly joined together to form structural elements on site.

The supporting structure is digitally planned by engineers and can be integrated into Building Information Modeling BIM). Compared to conventional materials, CPC panels are three to four times thinner and weigh less without losing load-bearing capacity. Thanks to pre-stressing, the rigid panels remain crack-free under service load.

Holcim’s innovative CPC technology has been recognized by Bauma, the world's largest trade fair in the construction industry, winning the Bauma Innovation Award 2022 in the “Construction” category.