Let’s talk transparency:

Scaling up EPDs

What is an EPD, and why is it so important for accelerating sustainable construction?

EPD stands for Environmental Product Declaration: it is an independently verified document that communicates a product’s environmental impact. An EPD can include up to 37 indicators, ranging from carbon footprint to energy consumption and waste generation. Think of it as the equivalent of a nutrition facts label for construction materials.

Backing products like ECOPact low-carbon concrete and ECOPlanet low-carbon cement with EPDs, construction industry specifiers – from architects to real estate developers – have full visibility on the composition and performance of sustainable building solutions. EPDs provide transparent, reliable product information that helps fuel demand for low-carbon alternatives.

The life cycle of concrete

EPDs are based on a standardized methodology that calculates the environmental impact of each stage of a product’s life, from manufacturing to usage and eventual disposal or recycling. In the case of concrete, the calculations are typically divided into three main phases:

1. Material production and placement

Extraction and processing of raw materials

Transport of raw materials to plant

Concrete production in plant and waste treatment

Transport to construction site

All processes associated with placing concrete (such as pumping or installation by crane) as well as production, transport and treatment of unused concrete

2. Use phase

Carbonation – the natural process by which concrete absorbs and neutralizes CO2 over time – during its service life

Maintenance, repair, refurbishment or replacement measures are typically not required during concrete’s service life

3. End of life

Dismantling and demolition of concrete structures; transport of demolished concrete for processing; concrete waste processing

The combined results across the product’s life cycle gives us a holistic picture of its total environmental impact.

In some countries, the potential benefit of recycling the concrete into new building materials (Module D) is also taken into account when calculating the environmental impact of a building.

The transparency that EPDs offer our clients allows them to make more environmentally sound decisions when realizing their projects, so we can build the cities of tomorrow in a more sustainable and low-carbon way.

The next generation of EPDs

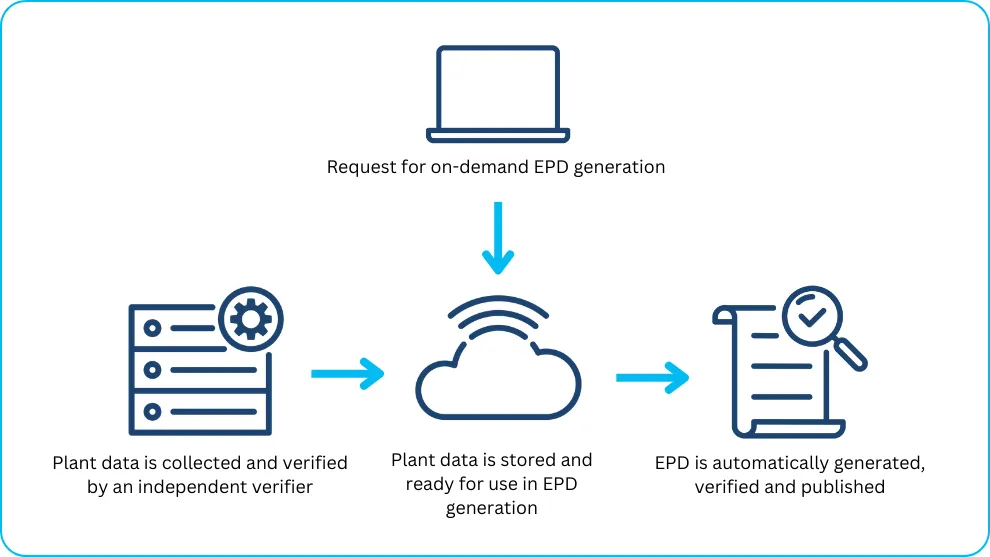

Building solutions providers traditionally produced EPDs through a manual, multi-step process that can take up to six months to complete.

In partnership with Climate Earth and the industry association Institut Bauen und Umwelt, Holcim has optimized and digitalized this process by launching the first on-demand EPD generators for concrete and cement products in Europe.

We are delighted to be working with Holcim on this critical project. Holcim has proven to be an innovative and visionary partner, showing a deep commitment to reaching net zero and an understanding of the strategic role that advanced software must play in measuring and managing the transition.

Instead of individually verifying each EPD, we can now instantly produce them using pre-verified plant data, taking the process from months to minutes.

Digitalizing EPDs is key to scaling them up: to date, Holcim has issued more than 3,000 EPDs across 24 countries.