Holcim’s carbon prestressed concrete technology wins award

Holcim’s low-carbon materials help decarbonize construction so that the world builds better with less using smart design. Thin precast carbon prestressed concrete (CPC) slabs are one of our latest solutions. CPC’s extraordinary potential to industrialize construction while driving low-carbon and circular building has made it the winner of the Bauma Innovation Award 2022 in the “Construction” category.

Reduces material use by up to 80% and is fully recyclable

Reduces CO2 emissions by up to 75%

Weighs less than reinforced concrete and timber

What are carbon prestressed concrete slabs?

In 2020, Holcim became an early investor in CPC AG, a Swiss start-up that invented carbon prestressed concrete (CPC) technology. Using high-strength concrete reinforced with prestressed carbon fibers, CPC slabs use a proprietary process and patented technology that gives them the same load-bearing capacity as traditional reinforced concrete slabs while being up to five times thinner and lighter. In addition to enabling resource-efficient construction systems, the absence of steel means a longer service life (up to 100 years), at the end of which the CPC systems can be disassembled and reused or fully recycled.

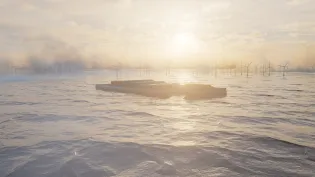

The Eulach footbridge in Winterthur, Switzerland gives just a glimpse of the possibilities.

Using traditional reinforced concrete, this nine-meter span would weigh approximately 56 tons (including its foundation). With timber, it would weigh 26 tons.

With CPC, the same footbridge weighs an amazing 14 tons. That’s 75% less than traditional concrete and 46% less than timber.

Over the whole service life, the CO2 footprint of the CPC bridge is up to five times lower than a concrete bridge and up to three times lower than a timber bridge.

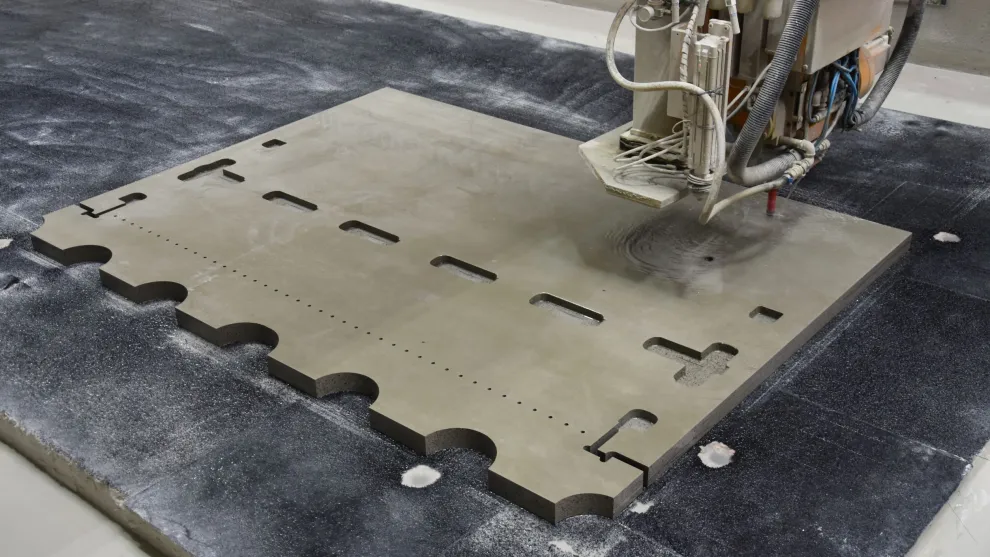

How is CPC made?

The CPC slabs are produced in a unique process with high degrees of standardization and automatization. CPC is a key element of industrializing construction similar to timber solutions, but with superior performance and a lower embodied carbon footprint. Through smart design, CPC helps us build better with less: construction systems using the thin, precast plates of concrete reduce material use by up to 80% and CO2 emissions by up to 75%, driving industrialized, circular and low-carbon construction.

“The partnership with Holcim gives us the opportunity to reach a larger market with our innovative thin precast concrete slabs. We can build better with less – emitting less carbon and consuming less natural resources.”

An award-winning solution

The technology’s incredible potential has already been recognized at Bauma, the world's largest trade fair in the construction industry, where it won the Bauma Innovation Award 2022 in the “Construction” category. The prize is a big recognition for all the efforts made by Holcim Germany and CPC AG to develop the technology and to build the first industrial production line for CPC. Their dedication has made this breakthrough technology available at scale for customers and building owners in Germany and neighboring countries.

“This technology has huge potential, especially for serial construction. Not only is it a great example of a low-carbon and circular solution, it’s also a testament to what we can achieve if we let open innovation thrive.”

A world of possibilities for construction

To build with CPC slabs, individual components are cut from large standardized plates and customized to fit any shape and size. These components are joined to create highly efficient construction systems in applications ranging from bridges and balconies to ceilings and facades. The prefabricated CPC solutions are then transported to the construction site for fast and easy installation.

There’s nothing quite like CPC anywhere else in the world. The technology’s potential is especially high for mature markets. So far, CPC has been certified in Germany, and has been used in over 170 projects in Switzerland.

Holcim Germany is ramping up production of CPC slabs at their plant in Essen to make this smart building solution available more widely.

Making green building possible at scale

At Holcim we are becoming a net-zero company, putting climate action at the heart of our strategy. We are at the forefront of green building solutions to make low-carbon and circular construction possible at scale around the world, from Manila to New York.

We are empowering smart design to use minimum materials for maximum strength like 3D printing that can use up to 80% less materials. We make this possible with our proprietary technologies from our 3D concrete printing ink TectorPrint to DYNAMax, our ultimate high strength concrete.

Across everything we do, we are building progress for people and the planet.