Partnering with leading startups to reinvent how the world builds

Imagine building the equivalent of Madrid every week. That’s what the construction industry is doing right now to accommodate the world’s growing population, and we’ll be doing so for the next 40 years. At Holcim we are leading by example – developing cutting-edge clean technology to drive sustainable building and make this growth work for people and the planet.

Innovation plays a key role in this process, and we’re pushing the boundaries in our sector – developing disruptive solutions through our R&D network and fostering a unique open innovation ecosystem, assessing hundreds of startups worldwide and investing in the best.

Through Holcim MAQER Ventures, our corporate venture capital and open innovation unit, we provide these startups with access to Holcim’s global operations and expertise, and ensure that every startup finds the right pathway to engage with us and scale breakthrough solutions – so that together we can reinvent how the world builds.

Let’s explore some of the most promising startups within Holcim’s portfolio.

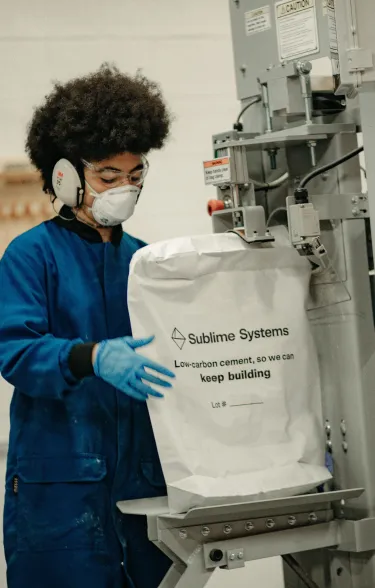

Sublime Systems

In September 2024, Holcim invested in Sublime Systems to scale its innovative, low-carbon technology and add to our broad range of technologies.

Challenge

The calcination process, where limestone is heated to produce clinker and substantial amounts of CO₂ are released, is the most carbon-intensive part of cement production. Additionally, cement production requires extremely high temperatures, which are typically generated by burning fossil fuels, resulting in further carbon emissions.

Technology

Sublime Systems’ process replaces carbon-intensive limestone with calcium silicate minerals or industrial waste, and uses an electrochemical method to decompose the raw materials at room temperature into their constituent elements. This innovative approach decarbonizes cement production by avoiding CO₂ emissions, without the added cost and complexity of carbon capture.

Impact

This approach enables more than 90% decarbonization in cement production. The process can be completely powered by renewable electricity, eliminating dependence on traditional kilns and significantly reducing energy consumption. The result is a low-emission cement product that does not compromise performance of the final product.

“Holcim’s investment has enabled us to advance construction on our first commercial manufacturing facility for Sublime Cement, a key step in our commercialization process.”

Leah Ellis, founder and CEO of Sublime Systems

Block Media

Paebbl

Together with Amazon, Holcim co-invested in Paebbl in October 2024 to scale the startup’s advanced mineralization technology that is designed to store CO₂ in concrete as a carbon sink.

Challenge

Beyond cement production, another challenge for decarbonization is the slow pace of natural CO₂ mineralization to form stable minerals, which takes place over hundreds or thousands of years. Paebbl’s technology accelerates the mineralization process.

Technology

Paebbl accelerates the mineralization process by converting CO₂ into future-proof industrial raw material. Using a low-energy process, the startup’s reactors convert CO₂ into a carbonated solid mineral, permanently storing captured CO₂ and repurposing it into carbon-neutral raw materials suitable for various industrial applications.

Impact

The output product can be used as a supplementary cementitious material (SCM) or filler in building materials, advancing cement decarbonization and contributing to the goal of net-zero emissions mitigating climate change.

“We are thrilled to welcome first movers in their respective fields, Amazon and Holcim, as first commercial partners to bring our vision to market.”

Marta Sjögren, Co-Founder and Co-CEO of Paebbl

Block Media

Travertine

We invested in Travertine in June 2024, to apply the startup’s proprietary circular technology to the decarbonization of cement.

Challenge

The upcycling of industrial waste streams, and the capture and mineralization of CO₂ emissions from industrial sources and the atmosphere.

Technology

The Travertine process creates a fossil-free source of sulfuric acid that helps minimize waste from mining and fertilizer, while enabling the critical element extraction needed for the energy transition. The approach also utilizes carbon mineralization to transform captured CO₂ into stable minerals, mimicking natural processes in a controlled and scalable process.

Impact

This technology has the potential to produce valuable materials for construction – including inputs for low-carbon cement – while embodying circular principles – and could potentially be applied across multiple industries globally.

“Decarbonization requires collaboration between actors across the construction value chain. We must finance novel projects, like Travertine’s, while mitigating risk – and with Holcim, we are doing just that.”

Laura Lammers, Founder and CEO of Travertine

Block Media

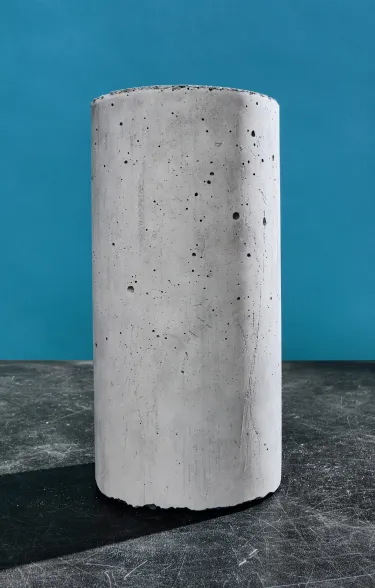

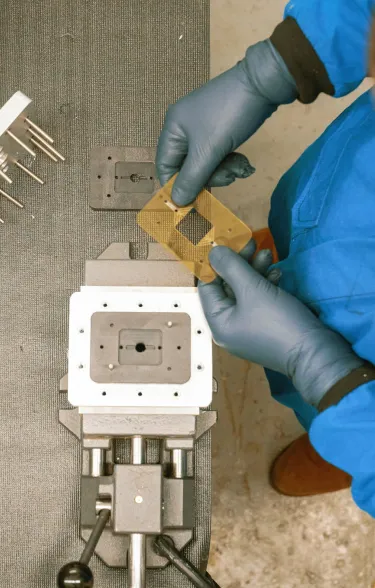

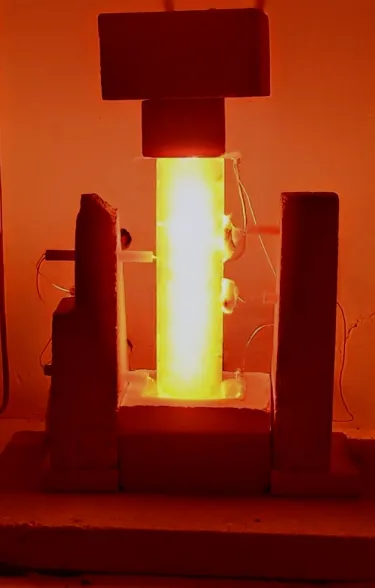

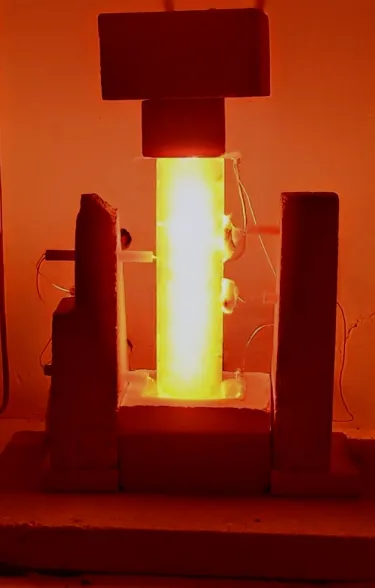

Electrified Thermal Solutions

Most recently, Holcim made a strategic investment in Electrified Thermal Solutions, aiming to advance zero-carbon heat, further strengthening our commitment to decarbonizing the built environment.

Challenge

Fossil fuels are traditionally burnt to achieve the ultra-high temperatures necessary for industrial processes like cement manufacturing, intensifying the industry’s carbon footprint.

Technology

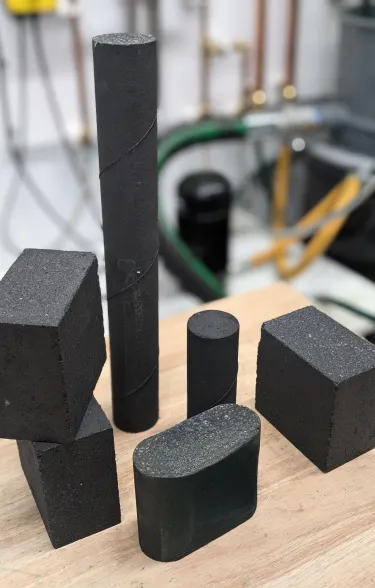

Electrified Thermal Solutions has developed electrically conductive firebricks, made from refractory materials, known as e-bricks, which are the heart of their Joule HiveTM thermal battery. This technology converts renewable electricity into high-temperature heat, capable of reaching temperatures as high as 1,800°C. Designed to replace fossil fuels with an electrical energy source, this innovation enables a reduction in CO₂ emissions.

Impact

This breakthrough innovation enables CO₂-reduced energy spend and helps energy-intensive industries rely more on renewables in their energy mix. This solution has the potential to accelerate Holcim’s decarbonization and help us achieve net zero.

"The world demands technology solutions that can do the job of fossil fuels affordably, scalably, and without carbon emissions."

Daniel Stack, Co-founder and CEO of Electrified Thermal Solutions