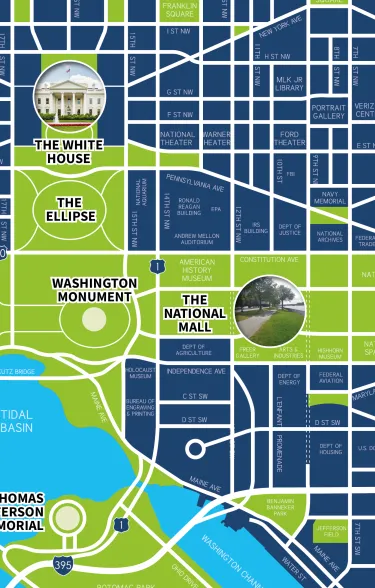

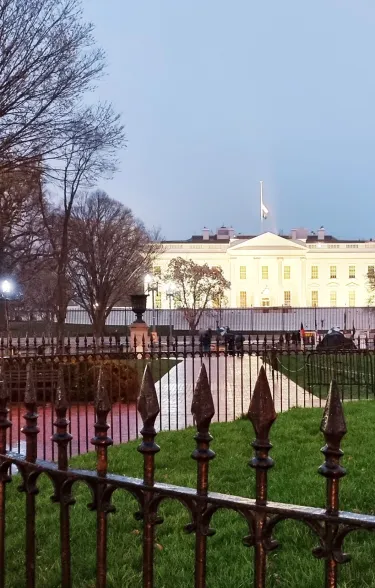

In line with today’s urbanization trends, Washington, D.C., is the world’s first LEED® Platinum city. The capital city of the United States is growing with new construction and renovation projects, many of which are LEED® Platinum and Gold certified.

Home to a high concentration of public authorities, architects and builders, D.C. is at the heart of influencing building norms, regulations and public opinion.

The city is also the locus of all federal governing bodies of the US, making it the place of origin of legislation, from the Infrastructure Investment and Jobs Act to the Inflation Reduction Act. This is where we can make our vision happen when it comes to evolving building norms to allow circular materials and building low-carbon infrastructure.

With iconic projects and operations representing the full spectrum of Holcim's innovative and sustainable building solutions, D.C. inspires Holcim in its commitment to accelerate green growth and decarbonize building.

Iconic Holcim projects in D.C.

PRODUCTION IN THE D.C. METROPOLITAN AREA

In addition to Holcim's building materials being used in landmarks across D.C., we also produce many of our products right in the surrounding area. With local production, we help close the transport loop and promote circularity.

Fort Totten

This 13-acre site is the region’s largest ready-mix production facility. The plant is at the forefront of supplying sustainable solutions including ECOPact, and has an on-site concrete recycling center for use of recycled concrete returns. The plant is equipped with a state-of-the-art water treatment facility and dual-source water supply. Fort Totten recently installed solar arrays to generate renewable solar energy on site, helping reduce fossil fuel reliance and power grid demand.

Bladensburg

This 18.8-acre site is a rail terminal that supplies crushed stone, ready-mix concrete and hot-mix asphalt to the D.C. metro area. Sustainability is at its core with a specialty blended, upcycled aggregate base that contains recycled concrete; asphalt mixes with up to 40% recycled asphalt; ECOPact production; and a ready-mix dual-source water supply.

Hagerstown cement

The Hagerstown plant supplies to the cities of D.C., Baltimore and Pittsburgh. Here we produce low-carbon OneCem (Portland Limestone Cement) with less clinker than traditional cement. 28% of the plant’s energy is supplied by solar panels. Using alternative fuels since 2008, the introduction of a newly-expanded low-carbon engineered fuel is planned for later this year. This system will replace up to 40% of traditional fossil fuel usage at the plant.

Rockville

This 330-acre serpentinite deposit with over 60 minerals identified has been supplying construction materials since the 1950s. Due to the urbanization of the greater D.C. area, the site is now surrounded on two sides by residential neighborhoods and the Serpentine Barrens Conservation Park. Rockville Quarry is active in community engagement. It hosts a biannual Earth Day Open House event for 2,000-3,000 people, which is recognized by the National Stone, Sand & Gravel Association.

Sparrows Point NewCem slag plant

Sparrows Point produces NewCem Slag. This offers high replacement rates for low-carbon concrete production. NewCem has an advanced sustainability profile that uses less energy for production than standard cement and contains recycled materials.

Fiberglass mat facility

Fiberglass mat is a key component in Malarkey Roofing Products sustainable shingles, used in residential roofing, and also in Elevate ISOGARD insulation and cover boards used in commercial roofing systems. Operations at the state-of-the-art plant began in 2023 to bolster production of our growing roofing solutions portfolio.

Baltimore Terminal

This terminal is geographically positioned to meet the cement demands of our customers in the surrounding region.

PARTNERING FOR SUSTAINABLE CHANGE

Amazon Web Services

Amazon Web Services (AWS) has partnered with Holcim to make AWS data centers in the US more sustainable according to its new design standards. These require that its new US data centers use concrete with 20% lower embodied carbon compared to standard concrete. Holcim allowed them to double that ambition, delivering a tailor-made ECOPact mix that decreases embodied carbon by nearly 40%. This mix has been used at the AWS data center near the International Airport in Dulles, Virginia.

Metropolitan Park

Furthermore, Amazon has committed to meeting net-zero carbon by 2040 and 100% renewable-energy use by 2030 in its Climate Pledge. The development of its new HQ, Metropolitan Park, is a cornerstone of this pledge. The entire development will be powered by energy generated at a new 45-megawatt solar farm currently under construction in Pittsylvania County, Virginia. Amazon will contribute to improving transportation, streetscape, utilities and public space, including a USD 20 million affordable housing contribution. They aim to achieve LEED® Platinum certification with their commitments to sustainable design.